Overview

Our research part of the project is focused on improving the performance of large cast iron components used in molds and dies. We’re doing this by developing a new material that combines cost-effective cast iron with a high-strength outer layer made of a special steel called maraging steel (18Ni300). The goal is to create a strong bond between these materials to make the final product both durable and efficient. We’re also exploring advanced techniques to enhance the surface quality of these components, ensuring they meet high standards of performance.

Process Chain

Technologies

Technology in Simple Terms: we prepared some content for “beginners” in AM technologies. Please check, there are always new interesting hints. Link

3D printing

Laser Metal Deposition (LMD) is an additive manufacturing (AM) process that uses a high-powered laser to melt metal powder and fuse it layer by layer onto a substrate to create a three-dimensional object. The process is often used to repair or add material to existing components as well as to create new complex metal parts. LMD offers advantages such as precise control over deposition, less material waste and the ability to work with a wide range of metals and alloys. The process is used in the aerospace, automotive and tooling industries, among others.

Six Q/A on 3D printing of metals

Plasma electro Polishing (PeP)

Plasma electropolishing is a surface treatment process that combines elements of both electropolishing and plasma technology. It involves the use of a plasma discharge to enhance the process. The high-energy particles in the plasma promote the dissolution of metal ions from the surface of the metal object. This helps to smooth out imperfections, remove roughness and improve the overall surface quality. The plasma also helps to remove impurities and oxides from the surface.

Understanding PeP Technology: Six Common Questions Answered

Samples before/after PeP machining

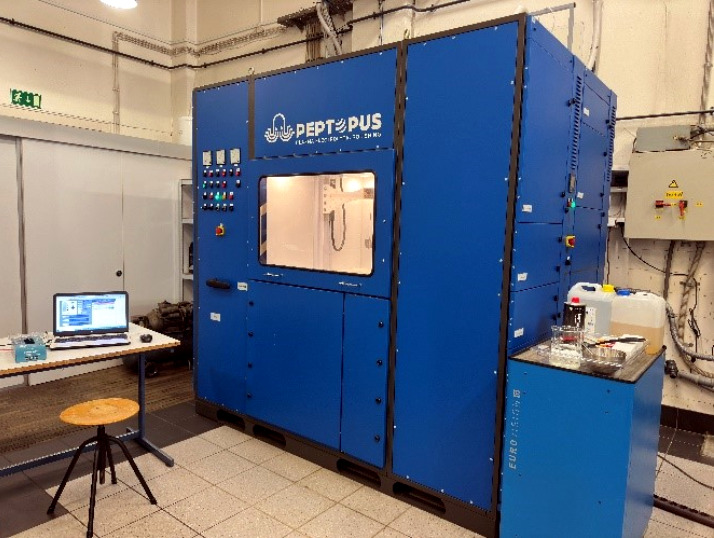

At the Laboratory for Alternative Technologies (LAT), our work within the SEAMAC project focuses on improving the surface quality of parts made using 3D printing techniques. We use a process called Plasma Electrolytic Polishing (PeP) to make these 3D-printed parts smoother and more uniform. The goal is to achieve an even surface on all sides of the parts, including areas that are typically rougher due to the printing process. We’re also studying how the orientation of the parts and the flow of the polishing liquid affect the final surface quality.

(a) PEP machine setup at UL-LAT

(b) an egg holder fabricated using metal 3D printing before and after plasma electrolytic polishing

Future Research

In the future, we plan to measure how much material is removed during the polishing process based on the shape and orientation of the parts. This will help us fine-tune the polishing process, especially when dealing with parts that have different materials in different areas. Our ultimate goal is to ensure that every part, no matter how complex, has a perfectly smooth and even surface.

Equipment & Infrastructure

Equipment & Infrastructure

Methods & Modeling

Methods & Modeling

Materials

The additive manufacturing of advanced alloys is a major research topic of the SEAMAC project. Experiments are conducted by combining cost-effective cast iron with a high-strength outer layer made of a special steel called maraging steel. The goal is to create a strong bond between these materials to make the final product both durable and efficient.

Functional Graded Material (FGM)

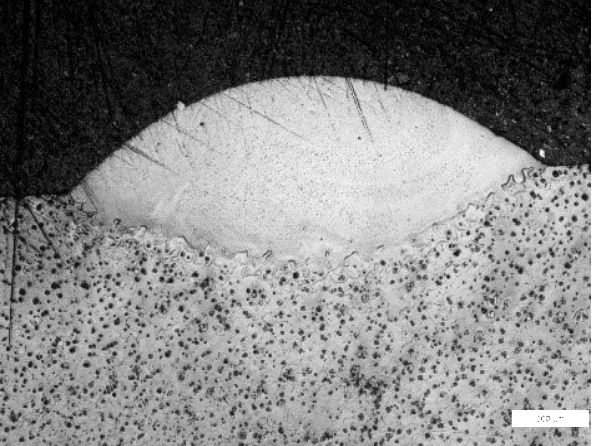

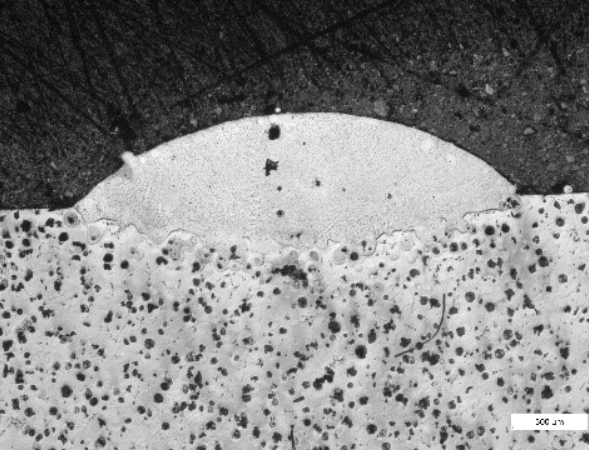

The SEAMAC project focuses primarily on improving the surface properties of gray cast iron using interlayer functional graded materials (FGM) produced by a laser-directed energy deposition L-DED of a metal powder. To improve the properties of the gray cast iron the maraging steel 18Ni300 in combination with In718, and FeNI—are used as potential interlayer materials. The investigation focuses on determining the optimal L-DED process parameters, such as laser power, mass flow rate, and scanning speed, to improve the diffusion of these materials with the cast iron substrate. Initial experiments, including single-line cladding, have shown that In718 exhibits superior diffusion properties without porosity (Fig. a), while 18Ni300 has some inherently favorable properties (Fig. b), but shows limited diffusion and low porosity. Conversely, application of FeNI has shown inadequate diffusion and high porosity (Fig. c). Further characterization, including microhardness testing, confirms these results and indicates that In718 is the most suitable candidate for use as an interlayer between managing steel and gray cast iron in the context of FGMs.

Fig. a) In 718

Fig. b) 18Ni300

Fig. c) FeNi

Microscopic diffusion analysis of cladding materials on GCI

Future/Planned Research

In the next phase, the SEAMAC project aims to investigate the application of the In718 to improve the surface properties of gray cast iron through a sharp interlayer as well as continuous FGM in the form of a thin wall and patch samples. The research will involve detailed characterization of these samples to evaluate their mechanical and chemical properties through various testing methods, including shear, tensile, hardness, scanning electron microscopy (SEM), X-ray diffraction (XRD), and electron backscatter diffraction (EBSD). It is expected that the results of the planned research will improve the understanding of material interactions and enhance the performance of gray cast iron-based structures in various industrial applications.

Characterisation

Measuring accuracy, integrity, and performance

Dimensional accuracy | Surface finish | Microstructure | Mechanical & corrosion testing

Case Studies & Demonstrators

Case Studies & Demonstrators txt

Publications & Data

Publications & Data txt

Resources

Resources txt