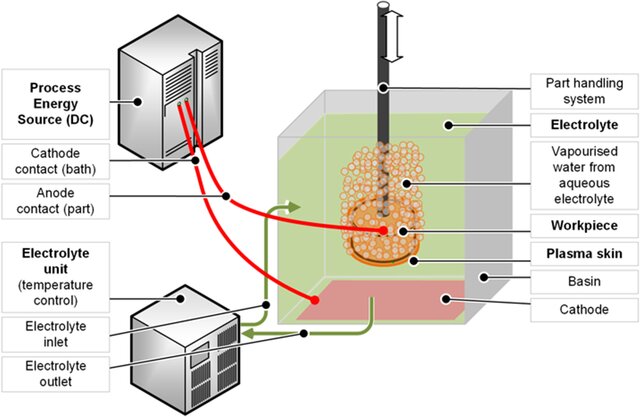

Q1: What is PeP (Plasma Electro Polishing)? A1: PeP, or Plasma Electro Polishing, is a surface treatment process that combines elements of both electropolishing and plasma technology. It utilizes a plasma discharge to enhance the polishing process, resulting in smoother and improved metal surfaces.

Q2: How does PeP work? A2: PeP works by using a high-energy plasma discharge to promote the dissolution of metal ions from the surface of a metal object. This process smooths out imperfections, removes roughness, and enhances the overall surface quality.

Q3: What are the benefits of using PeP? A3: The benefits of PeP include improved surface quality, the removal of impurities and oxides, and the ability to create smoother, more polished metal surfaces. It’s commonly used to enhance the appearance and functionality of various metal components.

Q4: Where is PeP technology used? A4: PeP technology is applied in various industries, including aerospace, automotive, medical devices, and more. It’s especially valuable for components requiring high surface quality and precision.

Q5: How does PeP contribute to the SEAMAC project? A5: PeP technology is an essential part of the SEAMAC project, contributing to the development and improvement of metal components in additive manufacturing. It plays a crucial role in enhancing the quality and functionality of 3D-printed metal parts.

Q6: Are there any safety considerations with PeP technology? A6: Yes, safety measures should be followed when working with PeP technology due to the use of plasma discharges. Proper training and adherence to safety protocols are essential to minimize risks during the PeP process.

Figure showing “Schematic presentation of PeP process” by Henning Zeidler http://dx.doi.org/10.1007/s12289-022-01659-7