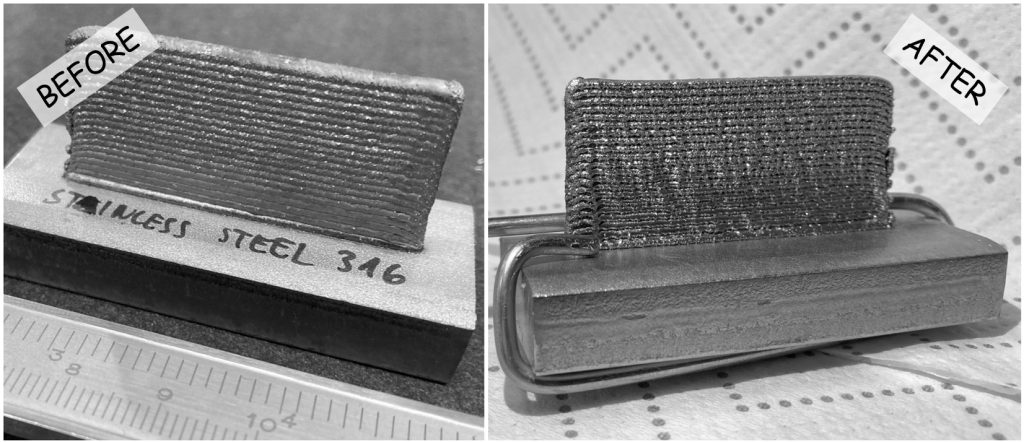

During his visit to Freiberg, SEAMAC coordinator Dr. Valentinčič, along with Dipl.-Ing. Toni Böttger, conducted experiments on polishing functionally graded materials (FGMs) using the Plasma Electrolytic Polishing (PeP) method.

Home of the SEAMAC project

During his visit to Freiberg, SEAMAC coordinator Dr. Valentinčič, along with Dipl.-Ing. Toni Böttger, conducted experiments on polishing functionally graded materials (FGMs) using the Plasma Electrolytic Polishing (PeP) method.

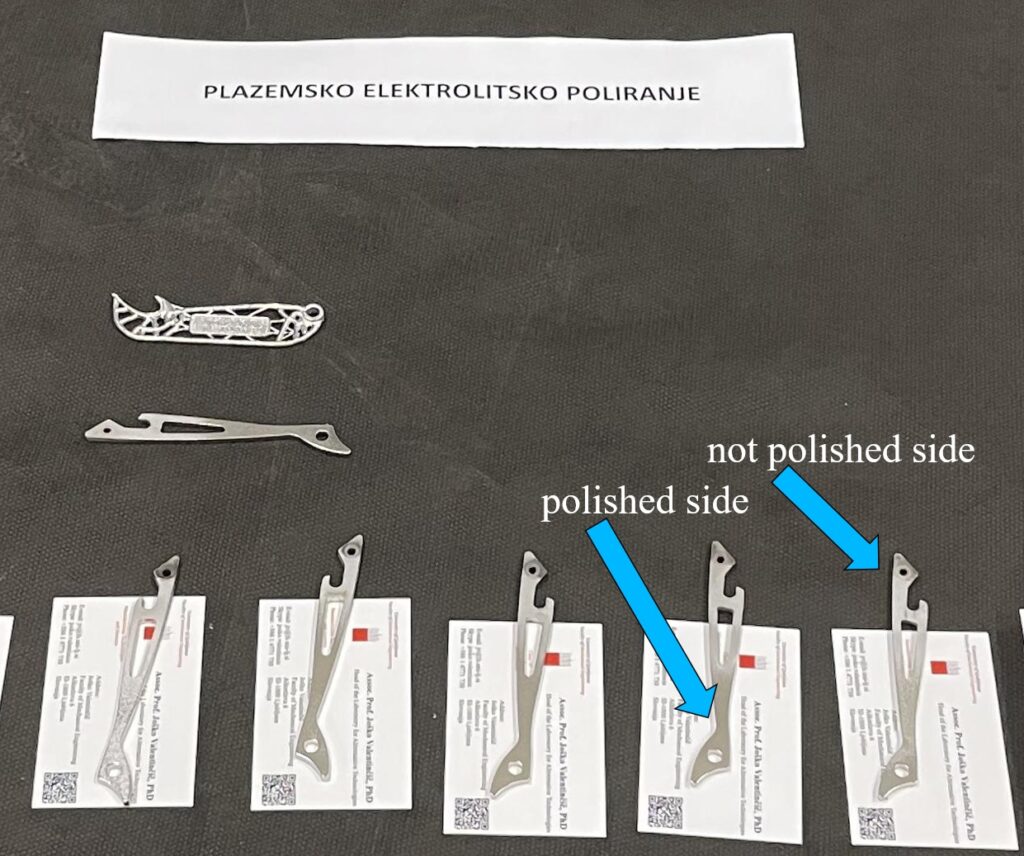

Every visitor received a sample of a stylized shark, which had undergone partial plasma electrolytic polishing (PeP) to highlight the effect of this innovative technology.

Some of the samples were polished also during the event.

With the newly acquired expertise, the first set of workpieces already shines.

The PeP machine was successfully connected and tested in November. An expert trainer from the machine manufacturer provided the UL members with comprehensive training.

The electrical cable for the PeP machine is ready: It’s not just a cable; it’s a super-cable! In its first few milliseconds, it flexes its muscles and withstands up to 1000 A. Thankfully, during its average workday, it chills out and cruises at just 10-100x lower current levels.

Yesterday, the PeP (Plasma Electro Polishing) machine arrived in Ljubljana, and today it has been successfully installed in its designated location at the LAT laboratory.

Participants of the Summer school on Additive manufacturing gathered in Haifa.

Only 12 Days Left Until the Exciting Start of the Summer School in Haifa! Get Ready for an Enriching Experience. Confirmation Emails Await All Registered Participants.